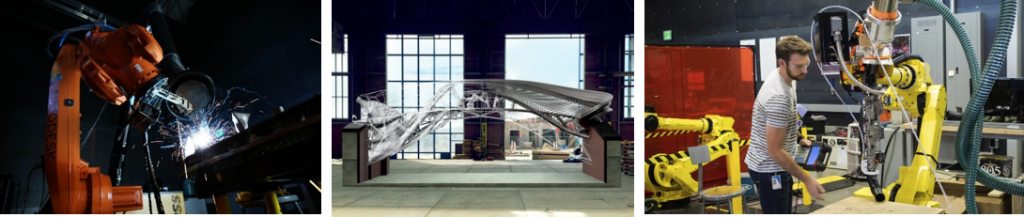

Technology innovators work together to advance the Future of Making Things at Autodesk University 2016 What happens when you bring an advanced research lab to a customer conference and put your most cutting-edge research on display for the world? You get the Future of Making Things experience at Autodesk University 2016. Dynamic and interactive, the Future of Making Things experience showcases disruptive technologies that are changing how the world around us is designed, made and used. Focusing on three of the most disruptive trends today, the experience demonstrates how generative design, industrial robotic fabrication and immersive VR design will soon become realities across all industries. Giant industrial robots 3D printing full size objects and incredibly complex geometries at high speed? Sure.  AR/VR experiences in photo-real resolution that allow authoring and collaboration with others regardless of where in the world they are? Of course.

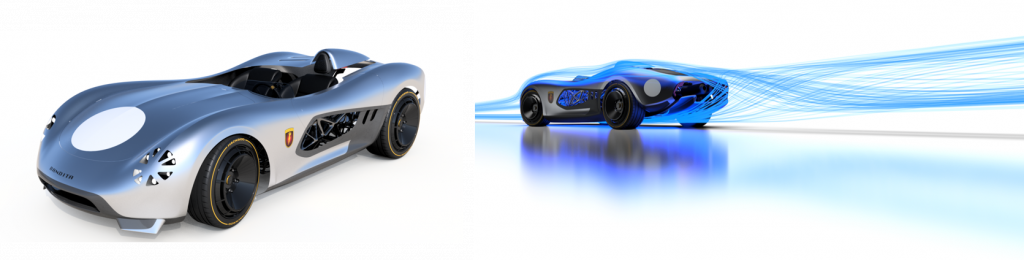

AR/VR experiences in photo-real resolution that allow authoring and collaboration with others regardless of where in the world they are? Of course.  And finally, the first ever generatively designed high performance sports car? You bet.

And finally, the first ever generatively designed high performance sports car? You bet.  What seems far-fetched is now very real and possible with the perfect blend of technology, innovation and partnerships. Autodesk is collaborating with a number of amazing companies to power the future of making things: NVIDIA: World’s most powerful Quadro and Tesla GPUs based on Pascal architecture power state-of-the-art Virtual Reality and accelerate Artificial Intelligence deep learning to make Autodesk vision of Generative Design a reality. For more information, visit https://blogs.nvidia.com/blog/2016/11/15/nvidia-at-autodesk-university/. HTC Vive: VR headset with 360 degree motion tracking with immersive “room-scale” experience. This allows people to walk around while in VR, and use controllers to vividly manipulate objects and experience immersive environments with precision. For more information, visit https://www.vive.com/us/. Lenovo: VR capable, the Lenovo ThinkStation P910 and P710 workstations power intensive apps for professionals in design, engineering, architecture and media & entertainment industries. For more information, visit http://blog.lenovo.com/en/category/workstation. SABIC: High performance polymer used in large format robotic additive manufacturing. Strangpresse: Polymer Extruder used in large format robotic additive manufacturing. Hack Rod: Democratized design, advanced manufacturing and epic storytelling. While most of these technologies are expected to reach the mainstream in the next 1-4 years, Autodesk is making them available today for those innovators who are shaping the Future of Making Things. How will you push the boundaries and shape the future of making things? To learn more about the future of making things, visit: http://www.autodesk.com/future-of-making-things

What seems far-fetched is now very real and possible with the perfect blend of technology, innovation and partnerships. Autodesk is collaborating with a number of amazing companies to power the future of making things: NVIDIA: World’s most powerful Quadro and Tesla GPUs based on Pascal architecture power state-of-the-art Virtual Reality and accelerate Artificial Intelligence deep learning to make Autodesk vision of Generative Design a reality. For more information, visit https://blogs.nvidia.com/blog/2016/11/15/nvidia-at-autodesk-university/. HTC Vive: VR headset with 360 degree motion tracking with immersive “room-scale” experience. This allows people to walk around while in VR, and use controllers to vividly manipulate objects and experience immersive environments with precision. For more information, visit https://www.vive.com/us/. Lenovo: VR capable, the Lenovo ThinkStation P910 and P710 workstations power intensive apps for professionals in design, engineering, architecture and media & entertainment industries. For more information, visit http://blog.lenovo.com/en/category/workstation. SABIC: High performance polymer used in large format robotic additive manufacturing. Strangpresse: Polymer Extruder used in large format robotic additive manufacturing. Hack Rod: Democratized design, advanced manufacturing and epic storytelling. While most of these technologies are expected to reach the mainstream in the next 1-4 years, Autodesk is making them available today for those innovators who are shaping the Future of Making Things. How will you push the boundaries and shape the future of making things? To learn more about the future of making things, visit: http://www.autodesk.com/future-of-making-things

Back

15 NOV 2016