Fusion 360 wouldn’t be what it is today without our customers. They use it to design and make incredible things, from lightweight motorcycle swingarms to powerful industrial processing equipment. As a cloud-based manufacturing ecosystem, it also wouldn’t grow without our customers, which is why we’re excited to announce three new sets of capabilities—capabilities that we’ve designed and implemented as a direct response to our customers’ needs. First up, a new manufacturing extension in Fusion 360 will cater to the more advanced requirements of manufacturing specialists, with flexible activation terms providing access only when you need it. Next, we’re integrating new cost insights for generative design, powered by aPriori, which will (for the first time ever) allow you to view manufacturing cost estimates for every design result in your generative study. Lastly, we’re adding two more manufacturing constraints to the generative design workspace, expanding the possibilities of what you can make with the technology.

Flexing Our Manufacturing Muscle

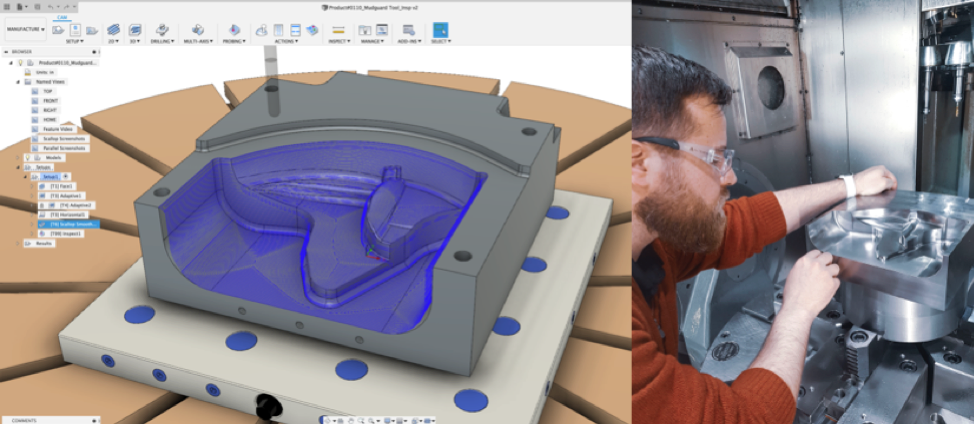

We recently introduced extensions for Fusion 360, which will enable you to switch on groups of high-end capabilities in Fusion 360 that are tailored to particular industry specializations.

A new manufacturing extension will be the first to enter the line-up. It’s a bundle of sophisticated Autodesk manufacturing technologies, reimagined and delivered in Fusion 360 to increase production efficiency. When activated, this extension will act as a hybrid manufacturing environment, letting users perform state-of-the-art processes like complex surface finishing, automated drilling, additive manufacturing, and automated verification workflows.

By using these automation and optimization tools during programming, you’ll generate more effective NC programs faster, yielding time savings across both programming and machining, resulting in a faster time-to-market. And if you’re the more refined type, the additional options to control your output will help deliver a higher-grade surface finish.

With our customers in mind, we’re making it easy to activate the extension on a short-term basis.

Learn more about Fusion 360’s new manufacturing extension.

Users can turn on the manufacturing extension in Fusion 360 for 125 cloud credits per month, per user, and gain unlimited access to its capabilities as long as it’s active.

Results at Any Cost

After unveiling generative design for Fusion 360 last year, many of you, our customers, dove straight into the technology and loved the program’s ability to compute solutions based on the design requirements you specified. Generative design can give you some incredible results that are optimized for your manufacturing method of choice, but how do you evaluate the tradeoffs between performance and the cost to make your part? It’s a challenge we’re keen to help our customers navigate.

With this in mind, we’ve partnered with aPriori to integrate manufacturing cost insights for generative design—so you’ll be able to view cost estimates for every result in your study.

We chose to work with aPriori because their product cost management solutions lead the industry in manufacturing simulation and cost insights. Their costing model accounts for geometry, material and manufacturing method— criteria that Fusion 360 users enter when setting up a generative design study. It will support all of the manufacturing options currently available for generative design today, in addition to future constraints that come to the workspace. It’s the first application of this technology for generative design, and we’re eager to get it into the hands of our users so they can make more informed decisions, more upfront in the design process.

“This partnership with Autodesk is very strategic for us,” said Stephanie Feraday, the president and CEO of aPriori Technologies. “We’re expanding our footprint into the concept design phase of product development, integrating the power of Fusion 360’s generative design with aPriori’s manufacturing simulation capabilities.”

APriori will analyze each design variation created with a generative design study to identify its manufacturing cost range. Whereas other product costing solutions on the market require significant manual input by highly trained experts, aPriori’s solution for generative design is entirely automated.

“We’re also seeing future opportunities to extend the insights provided with each generative design study, said Feraday. “We could potentially include not only cost, but also manufacturability guidance, which will make the selection of design direction even more efficient.”

New Constraints for Your Consideration

As you can see, we’ve been hard at work to make generative design more valuable for our users. In addition to upcoming cost insights, we’ll be adding two more manufacturing constraints to the workspace. Coming soon as a technology preview, a new die casting constraint for generative design will bring together next-generation design technology with one of the industry’s most established manufacturing processes. Those who use the casting process know it’s is an ideal method for high-volume and high-performance applications in the aerospace, automotive and medical industries because it allows you to scale production of your generated parts with a higher degree of precision than traditional machining.

After casting, we’ll see the addition of 2.5-axis milling, which will enter the lineup of existing CNC constraints available for your generative study: 2-axis cutting and 3- and 5-axis milling. This constraint will make it even easier to practically manufacture your generative design results, with the processes and machinery you already have in place.

As the industry continues to transform, we believe there’s almost always a way to make something better. And no matter what “better” means to you—cost efficiency, strength and performance, or product innovation— we’re excited to be bringing you more tools and technologies to get you there.