It’s that time once every four years when people have summer sports on their mind, so we got to wondering what the future holds for sports equipment and athletes. Over the last 100+ years, we’ve seen dramatic improvements in the design of gear such as bicycles, in terms of weight, materials, aerodynamics and more.

Now with algorithmically driven generative design, we are at the cusp of a revolution in sports equipment design and manufacture. Human designers work with computers to define design constraints and objectives, then get back thousands of sometimes otherworldly design options that meet the specified requirements.

What might this look like …

… for athletic shoes?

Mid 19th century running shoes were essentially leather slips with hard rubber soles, shown in the top left corner. Canvas shoes with softer rubber soles started to appear around the dawn of the 20th century, and by the 1960s, shoes looked like the pair shown in the bottom left corner, which were worn by world class runner Arthur Keily.

Athletic shoe innovation took off in the 70s and 80s as major manufacturers aimed to create better fit while reducing weight and increasing comfort. By 2016, rhe UA Architech launched with a 3D-printed, generatively designed sole for cushioning and support; in the near future generative design could lead to mass customization of athletic footwear based on the shape of an Olympian’s foot and the specific performance needs of their sport

… for bicycles?

Cycling has been a mainstay in modern global competitions, and the sport leapt forward in the late 1800s and early 1900s with the advent of gearing and derailleurs. In the 1980s, rear gear clusters began being built with more cogs, resulting in a greater number of speeds available to riders.

Modern day bikes are all about aerodynamics and lightweight components, often featuring deep-dish or disc wheels that reduce drag. A generative design tool such as Autodesk Dreamcatcher could produce outside-the-box, lightweight frame geometries that are strengthened by internal lattice structures; this bike looks fast!

… for recurve archery bows?

Recurve bows feature long arms and a single string. They were used in global competition as early as 1900. While the sport fell off the international stage for sometime, it’s popularity re-surged and archery hit the global stage again in 1972, obviously with equipment that was much improved.

Modern recurve bows are often made of carbon fiber; some also use an incompressible synthetic foam to resist deformation of the long arms when the bow is drawn. The Optimal recurve bow, by artist John Briscella, is a user-centered design customized to the archer’s hand and needs, while also accounting for material properties of strength, weight and performance engineered to account for forces applied to the form; generative design could be used to develop materials for better bow performance and greater customization for individual archers.

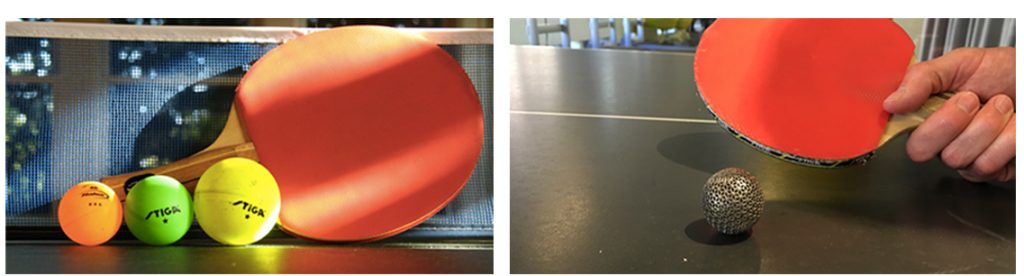

… for table tennis balls?

In competition, there are strict rules governing the mass and diameter of table tennis balls. For example, Olympic table tennis must be played with a sphere having a mass of 2.7 grams and a diameter of 40 millimeters. A generatively designed table tennis ball could be engineered for greater structural strength and durability while meeting international specifications for mass, diameter, and air resistance; no more easily squished ping pong balls!

… for the athlete herself?

World-class German cyclist Denise Schindler partnered with Autodesk to explore how new technologies and manufacturing techniques could be harnessed to increase the accessibility of sports prostheses. Denise’s new prosthesis was modeled using advanced cloud design tool Fusion 360; the weight of the prosthesis was reduced by harnessing the lightweighting power of Autodesk Within generative design software. This new custom prosthesis is such to give her an edge in upcoming competition!